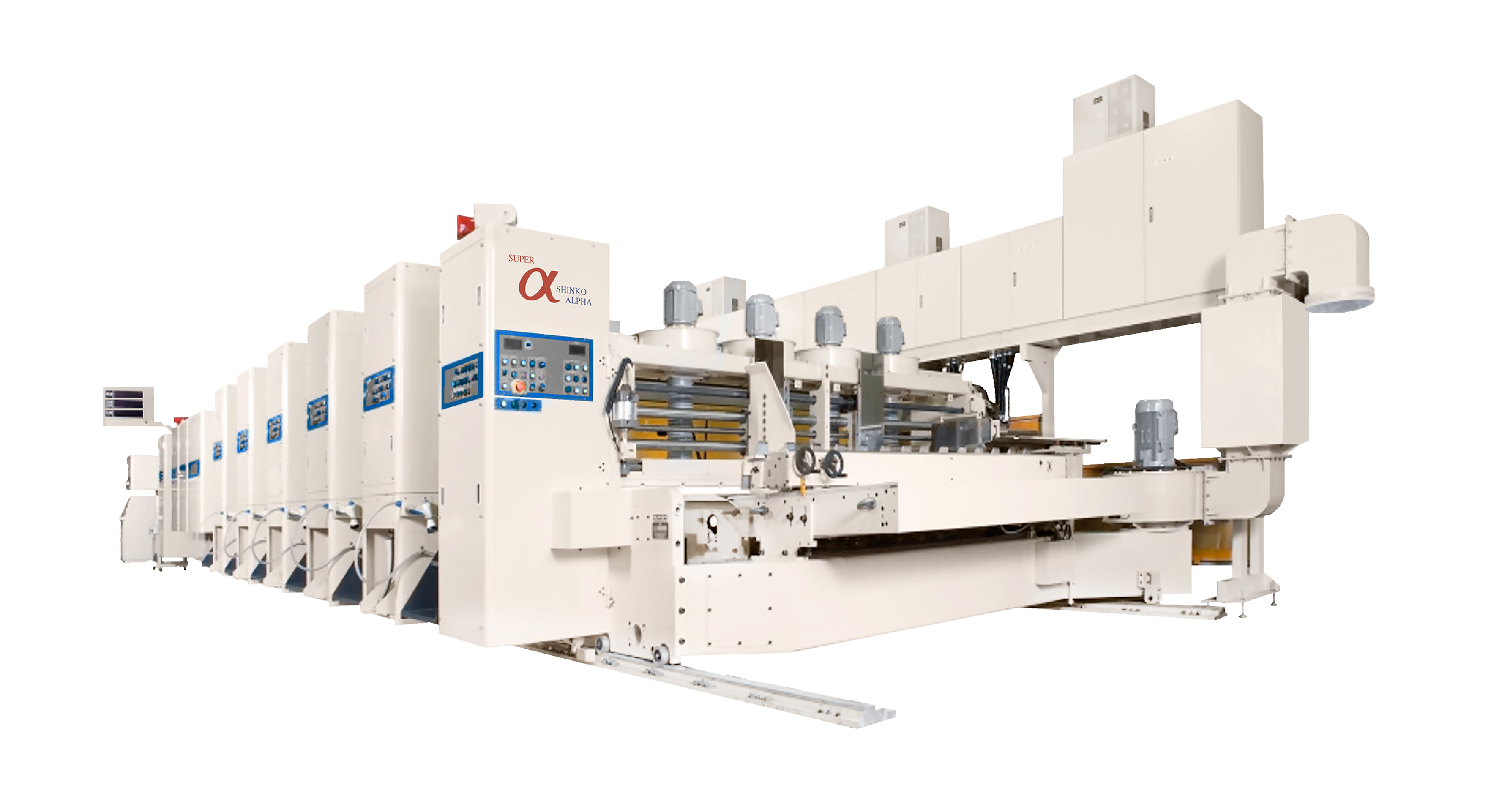

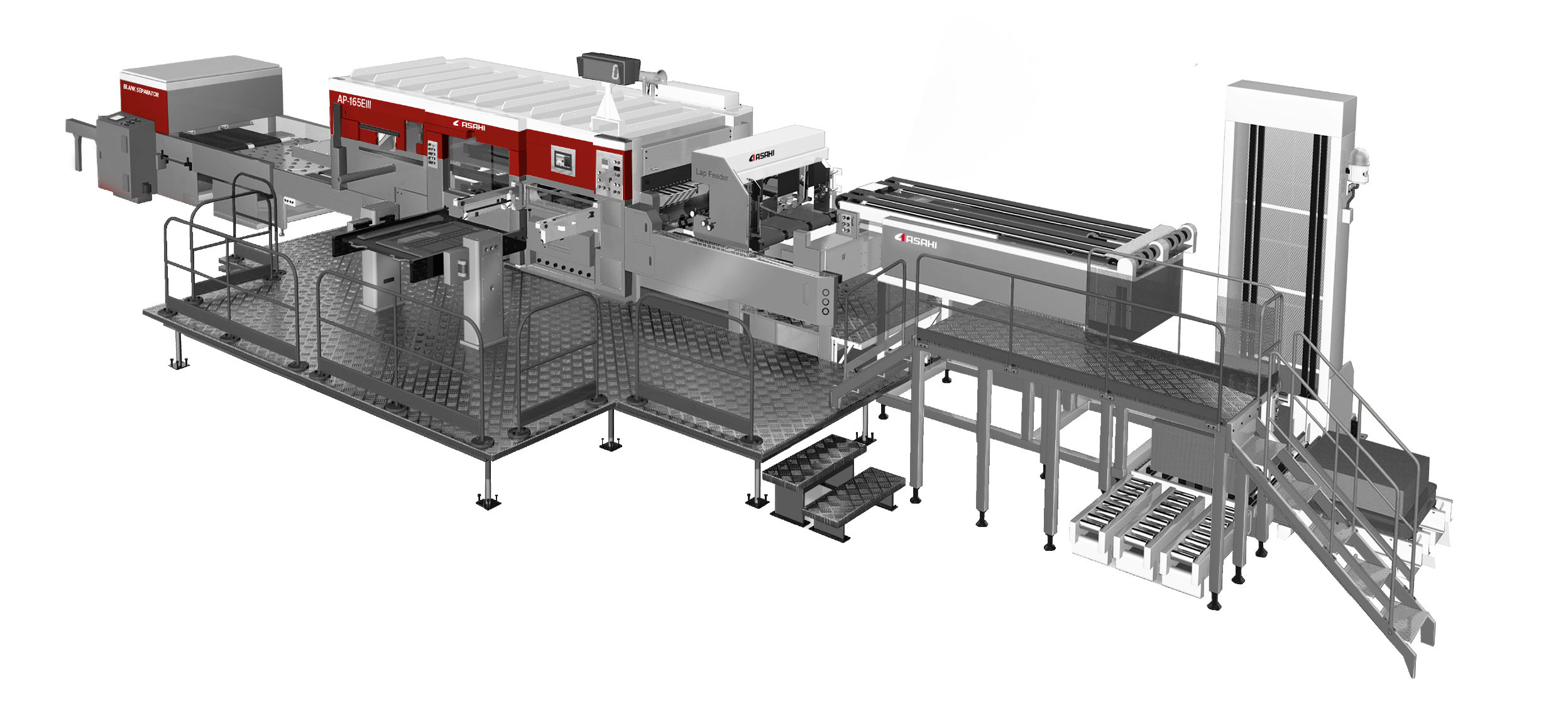

Asahi AP165EII

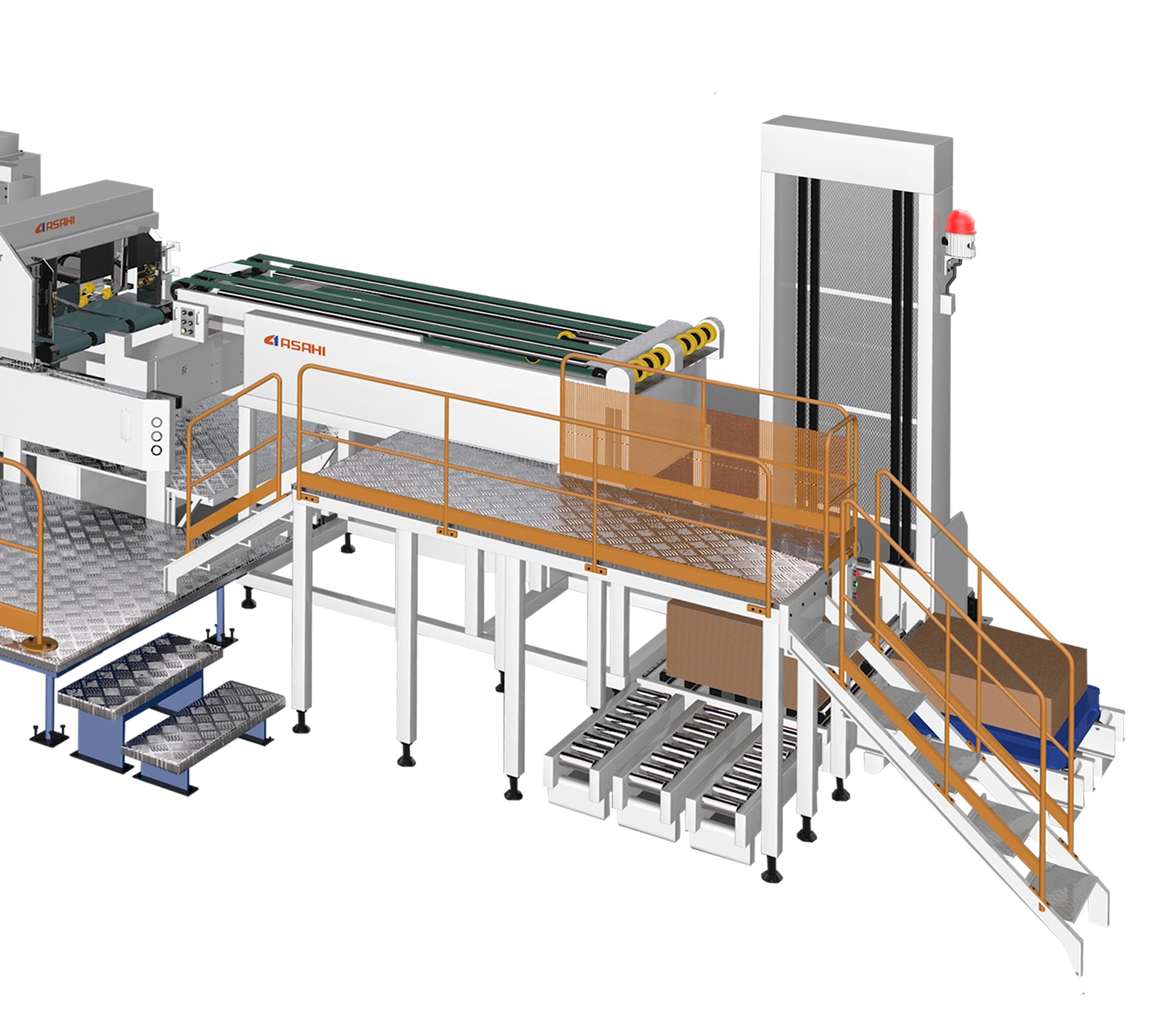

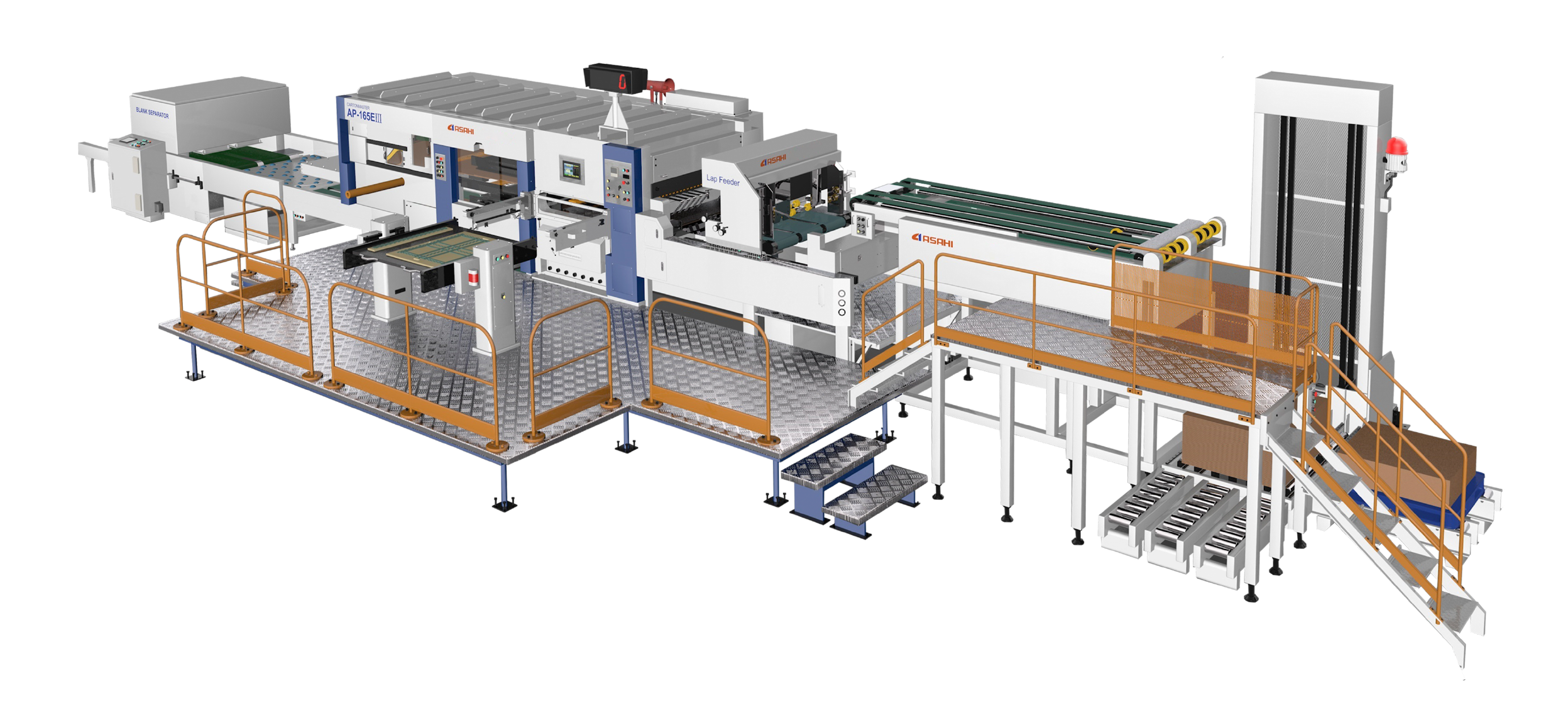

The AP-165EIII automatic flatbed die-cutting press (Asahi, Japan) is designed for complex die-cut packaging, including microflute cardboard. The LAP FEEDER aligns blanks before gripping, while vacuum belts enable work with warped material. The press supports large blanks up to 1200x1650 mm. The package includes a hydraulic lift table, feeding, die-cutting, waste removal, and product unloading sections.

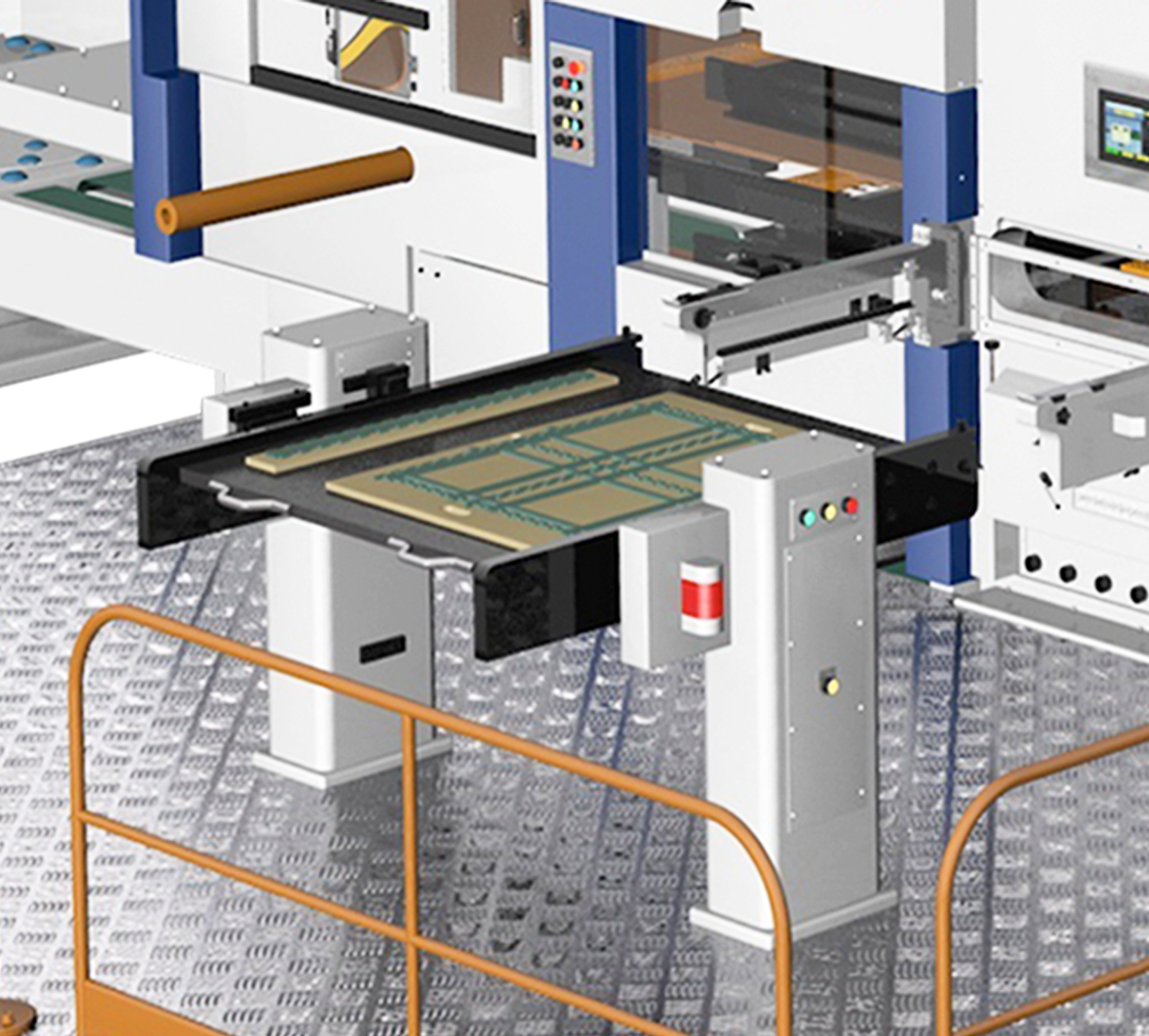

Line nodes

Key Features:

- Engineered specifically for the corrugated board industry, featuring an advanced Lap Feeder system with servo-controlled vacuum suction belt.

- Precision die-cutting capabilities for a wide range of materials, from micro flute to double wall corrugated board.

- Complete stripping functionality enabled via an integrated stripping section and gripper edge waste removal system.

- Versatile and adaptable design suitable for both small and large format production.

- Equipped with state-of-the-art safety systems for enhanced operational security.

- All functional controls are externally accessible, and die-cutting tools are inserted from the machine exterior for ease of use.

- Supports multi-out formats efficiently, utilizing the latest technology within the delivery section.

Сharacteristics

Technical data

| Maximum sheet size: | 1200×1650mm |

| Minimum sheet size: | 500×600mm |

| Maximum cutting size: | 1180×1630mm |

| Gripper size: | 15(±5)mm |

| Die-cutting Accuracy: | ±0.5mm |

| Maximum operational pressure: | 400 tons |

| Applicable thickness of corrugated board: | 1-9mm |

| Maximum speed: | 5500 i.p.h |

| Required power supply: | 36KW (main motor 22KW) |

| Net weight of machine: | 38 tons |

| The specification is subject to alteration without notice | |

Video

Documentation