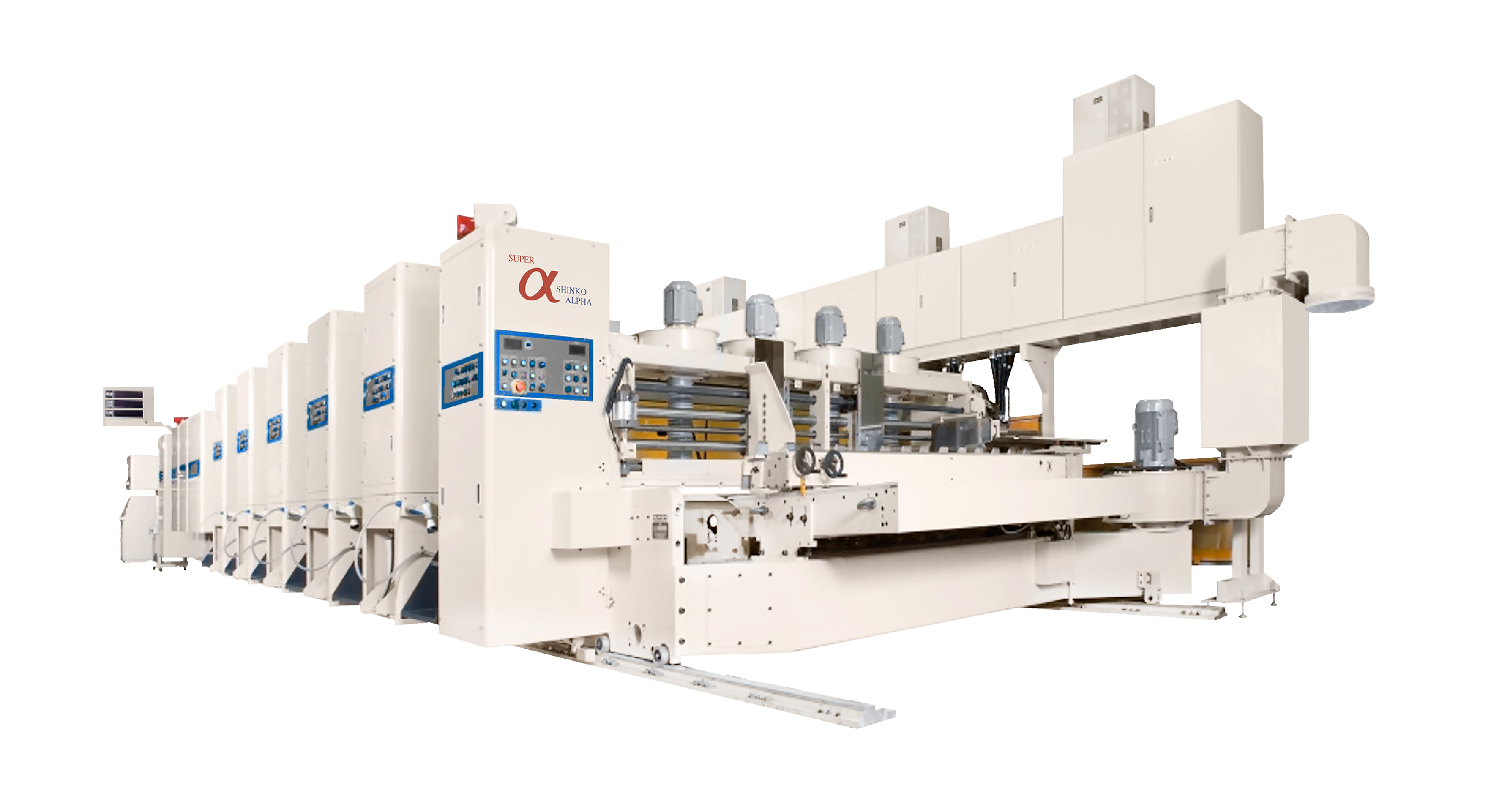

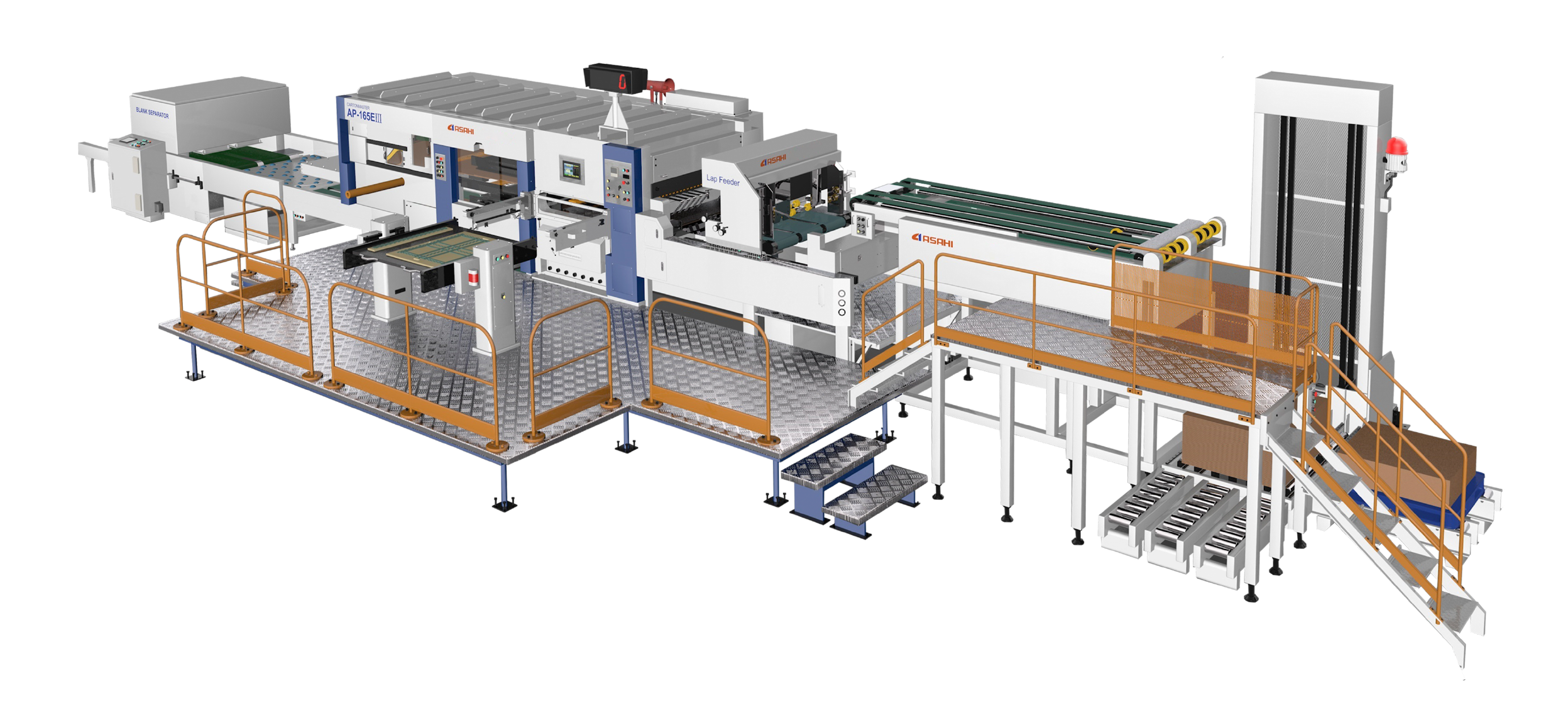

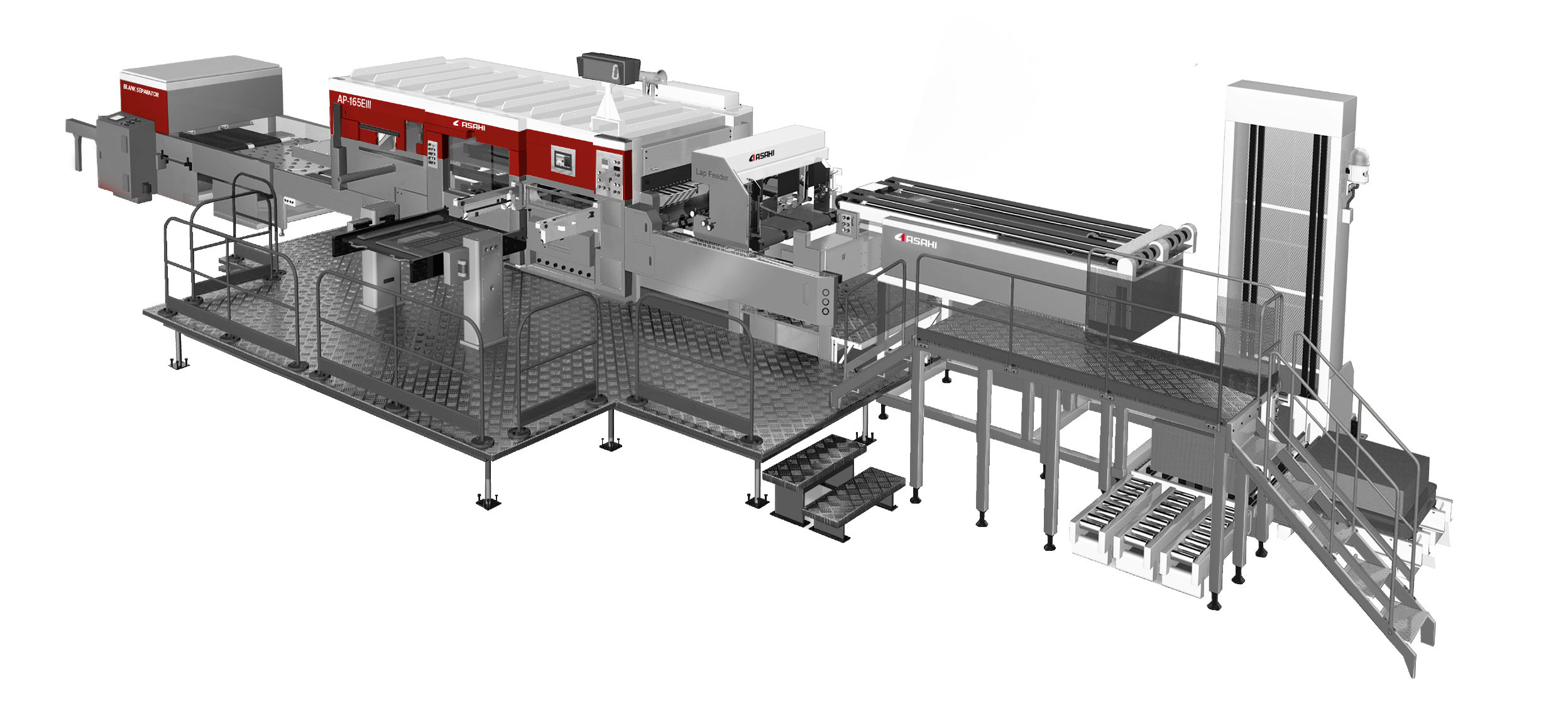

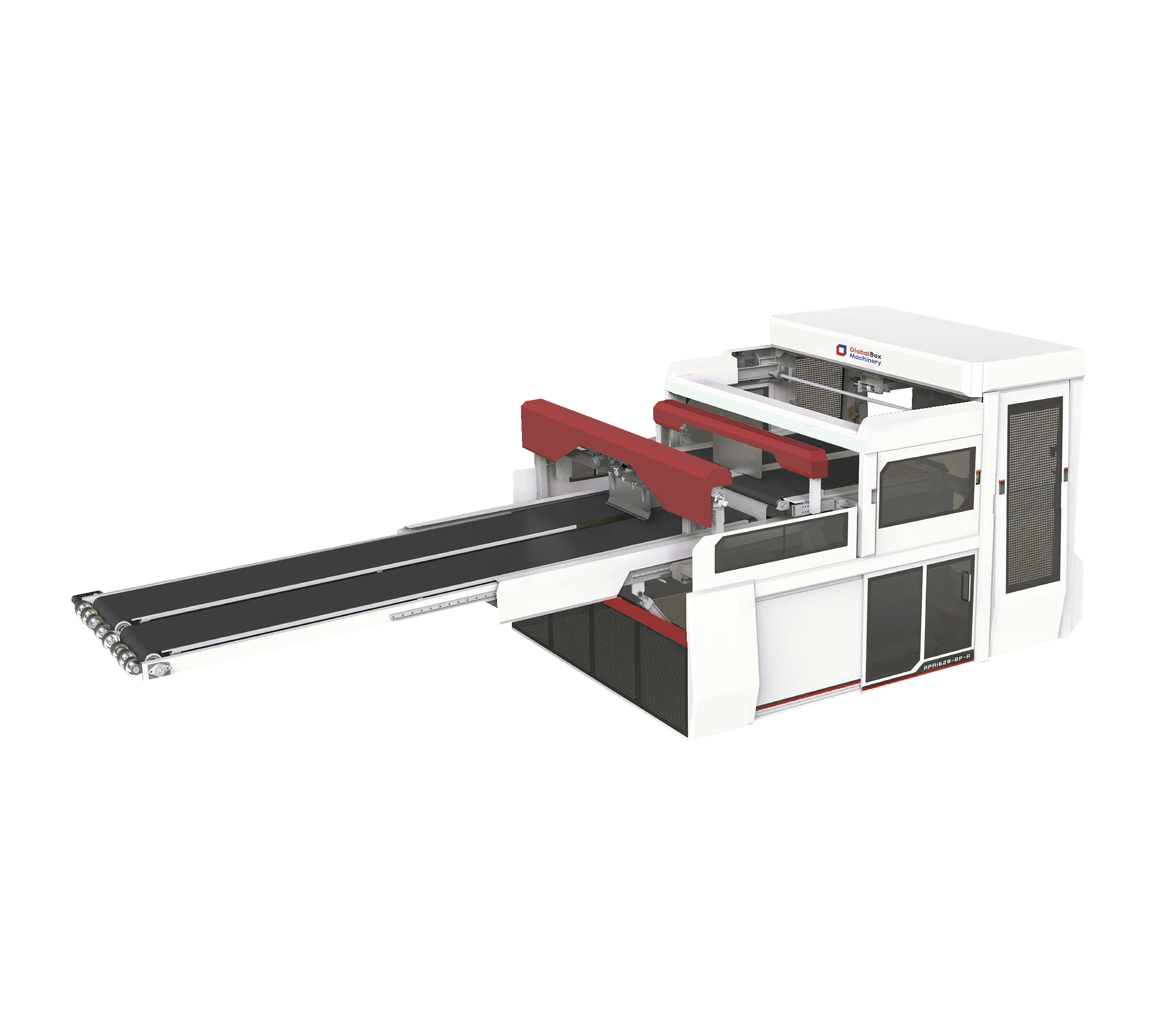

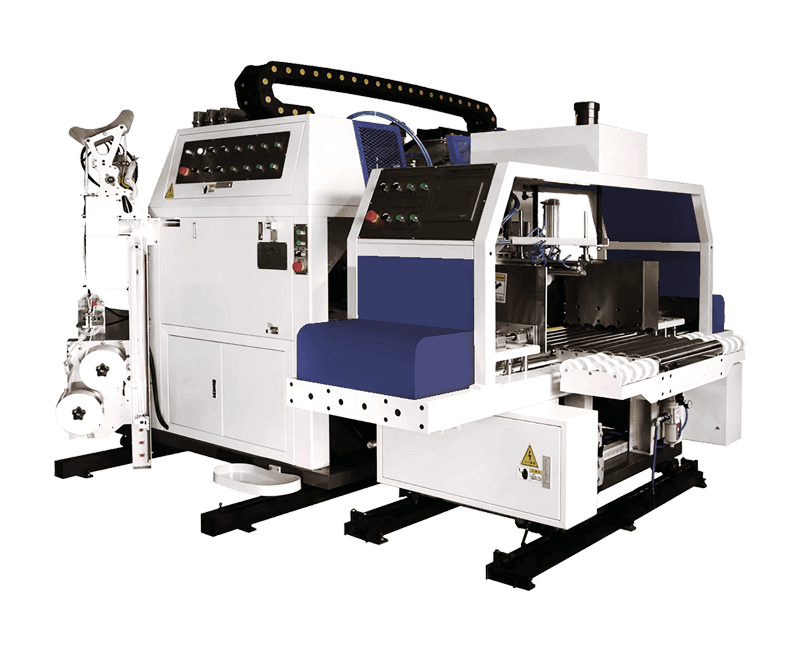

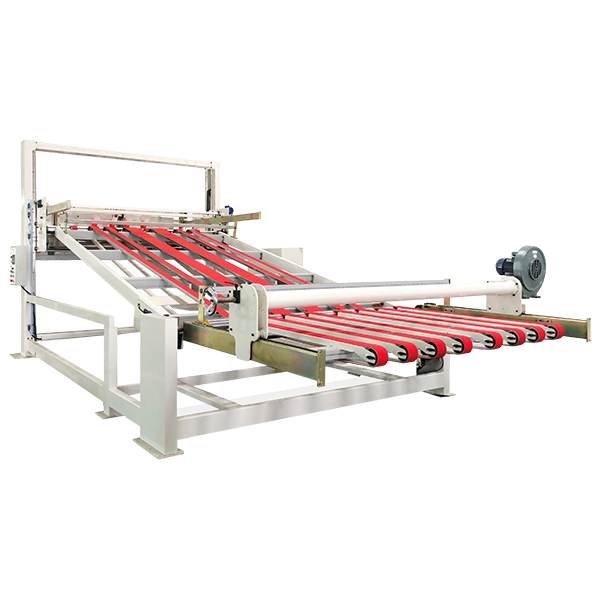

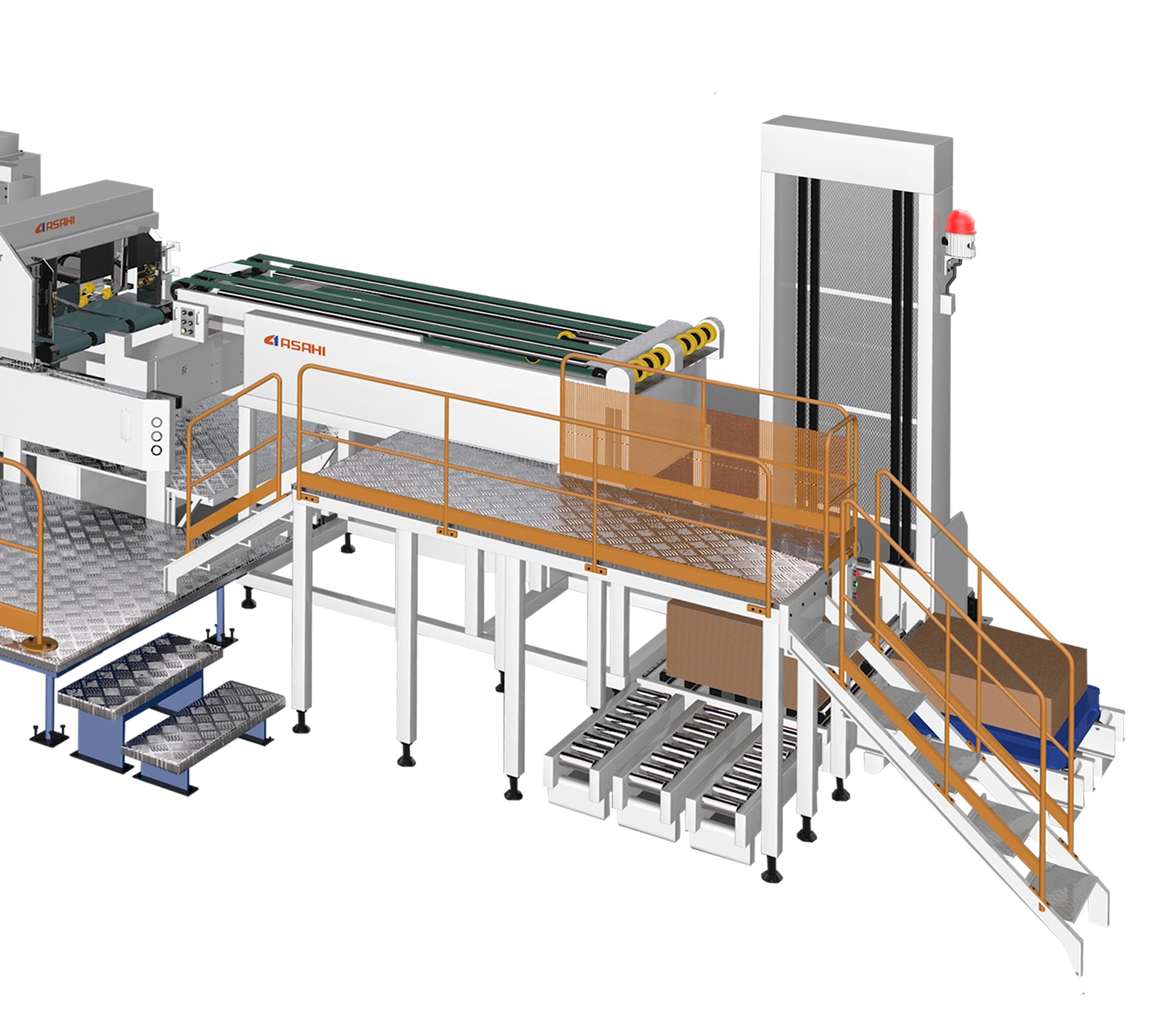

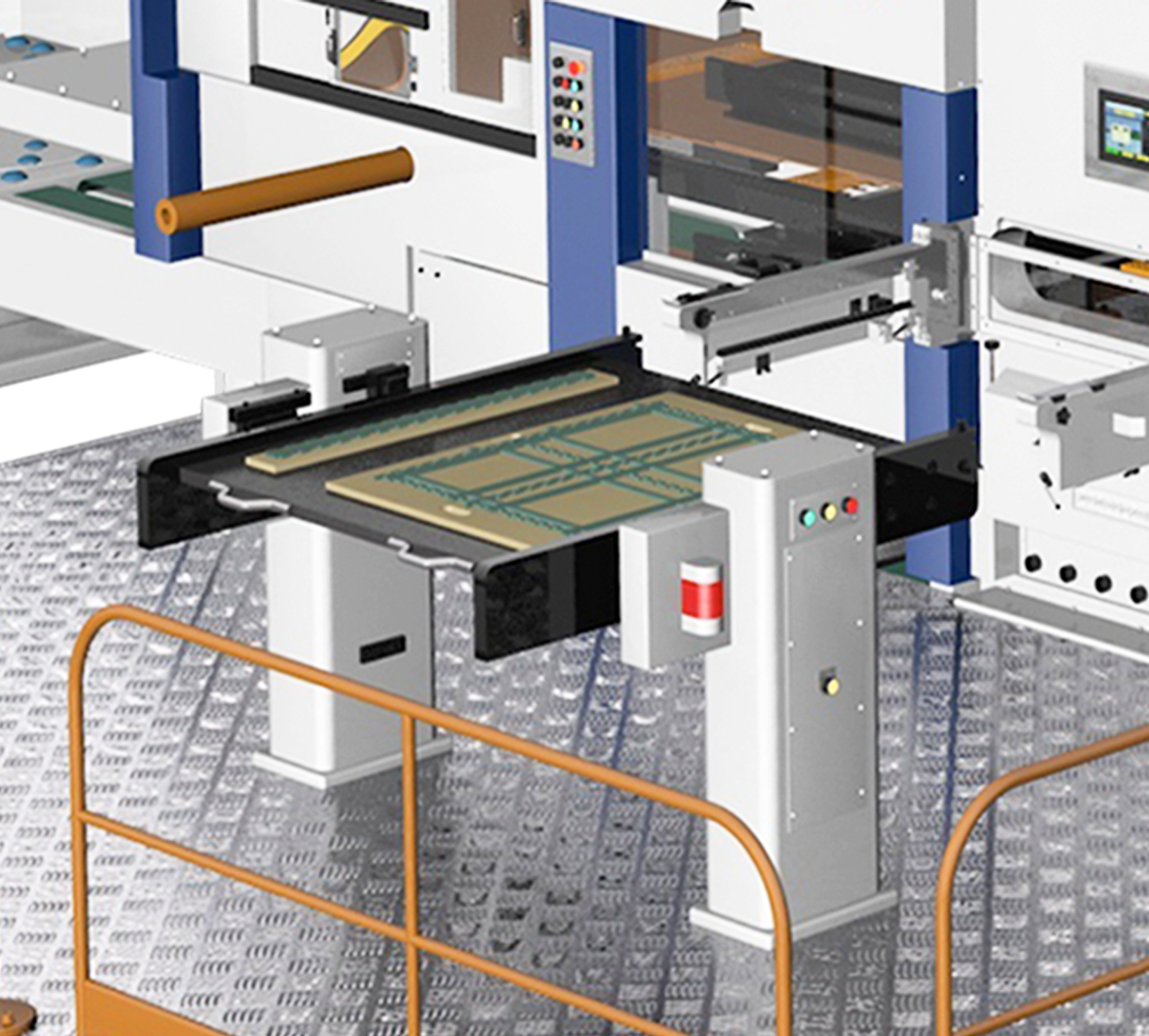

Equipment

Our Product Portfolio

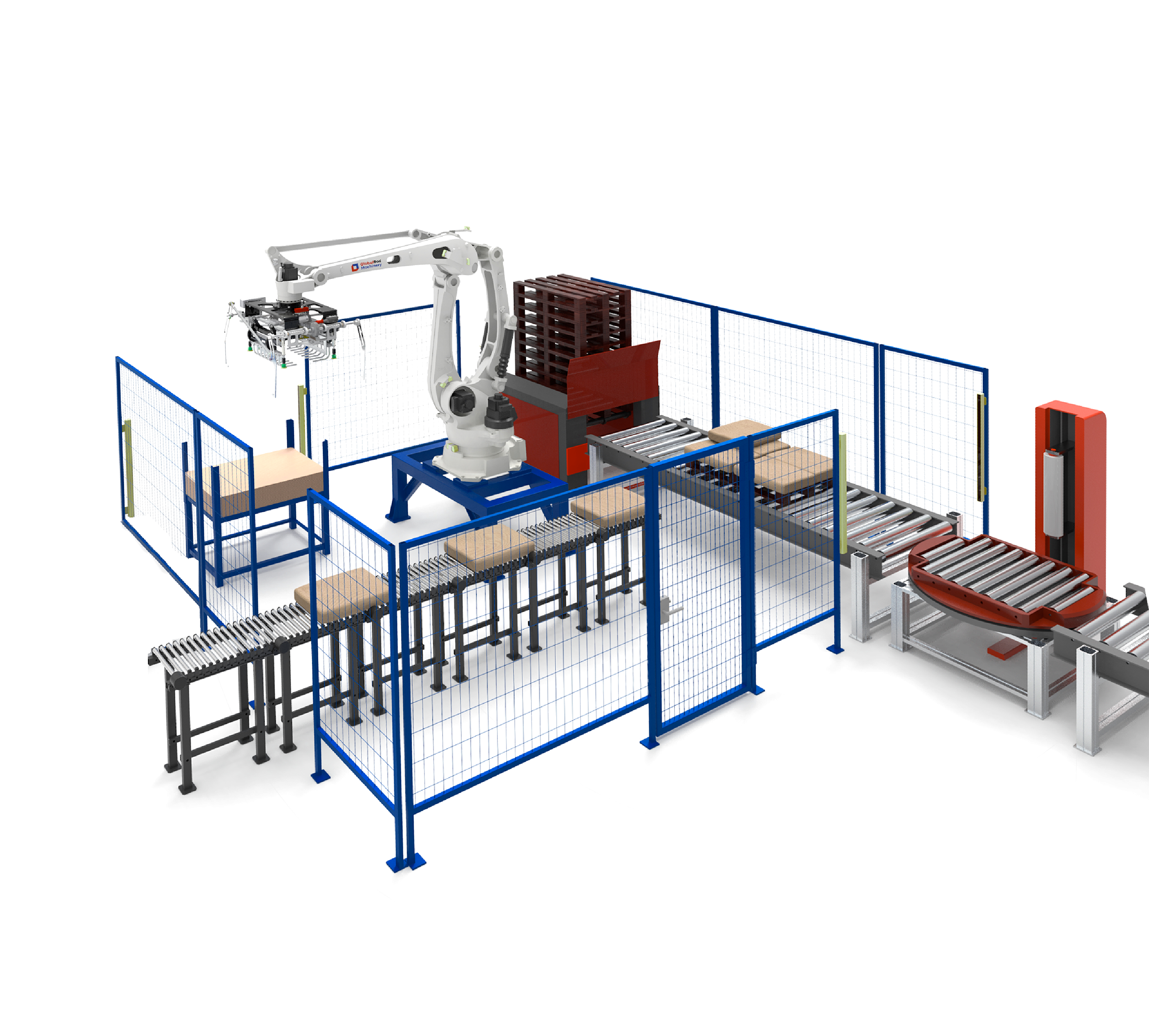

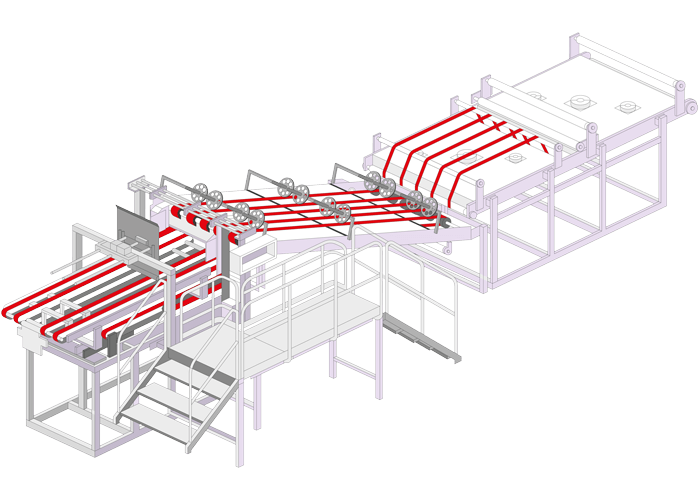

Solutions

Our Application Solutions

Who we are

About company

GlobalBoxMachinery Group is the world's largest machine–building holding of the corrugated industry. The head office is based in Guangdong Province, PRC.

The group includes such manufacturing giants as:

- Shinko Machine Co. Ltd. (Japan)

- Shinko Machine PRC Co., Ltd. (PRC)

- Asahi Nantai Co., Ltd. (PRC)

- Keshenglong Carton Packing Machine Co., Ltd. (PRC)

- Technopark Baosheng Foshan (PRC)